Internet of Things in reverse vending: The invisible tools powering smart recycling

In recent decades TOMRA’s reverse vending machines (RVMs) for drink container recycling have become more intelligent and efficient than ever, as the company’s engineers design them with the latest technology and digital solutions – and at the heart of these solutions is the Internet of Things (IoT).

What is the Internet of Things (IoT)?

Put simply, IoT is a network of connected devices that use the internet to collect and share data.

We see many instances of this in the gadgets and technology we rely upon today. Smart watches and fitness trackers are a perfect example, and IoT-enabled systems control everything from lighting and heating to security cameras and even coffee machines.

Businesses also use IoT to improve operational efficiency and drive growth. It is used across a vast range of sectors such as manufacturing, retail, energy, agriculture and more.

The Internet of Things and recycling

The world of recycling and waste management is no different, with IoT optimizing the recycling process in areas such as identifying, sorting and tracking recyclables.

TOMRA Collection was an early adopter of this technology, which is now used to connect tens of thousands of its reverse vending machines worldwide.

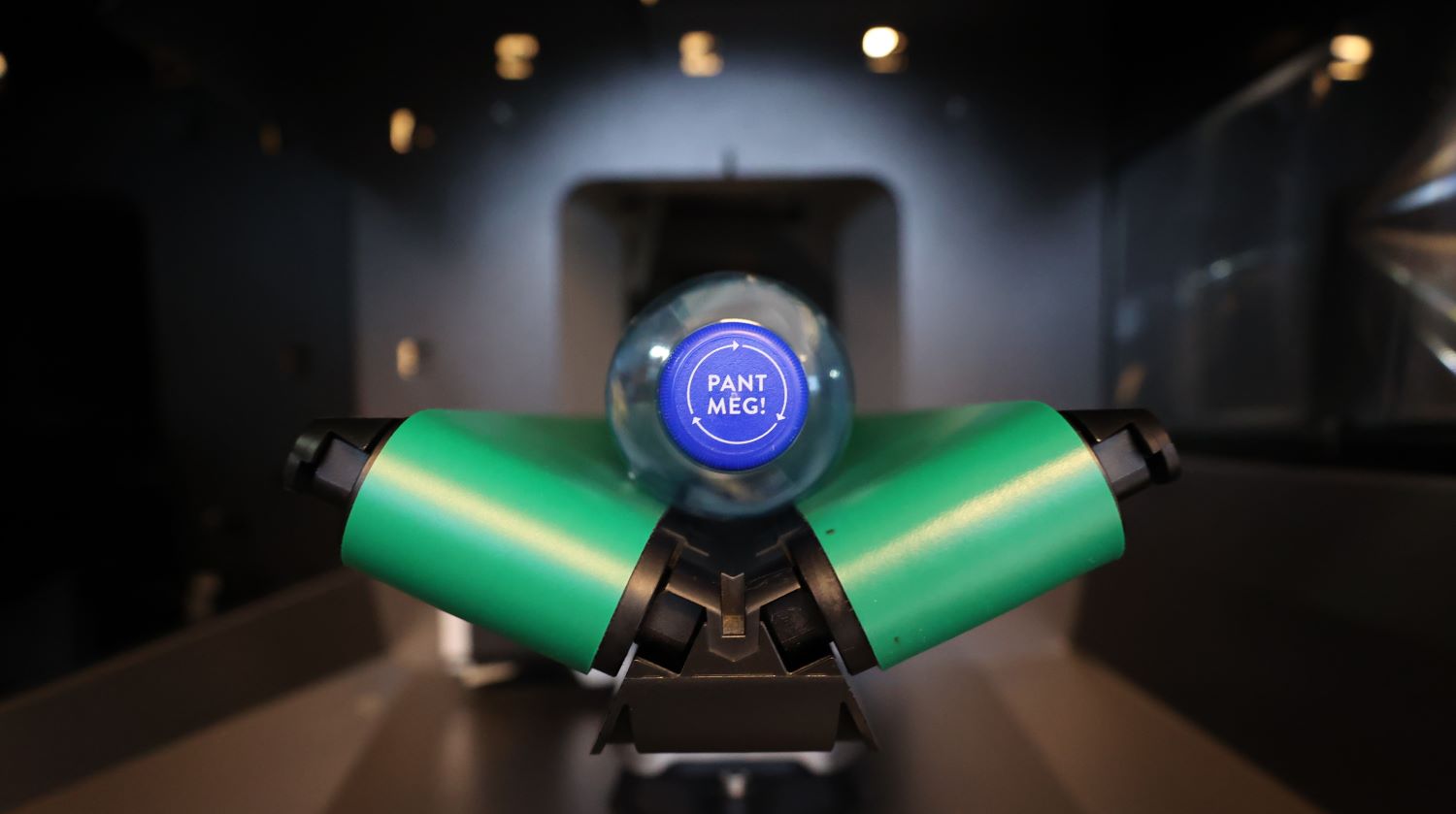

When people use our machines they see a place for their empty drink containers, but there is an immense amount of technology driving it.

“Inside a reverse vending machine are around 1,500 - 2,000 unique components, and these are connected to our digital tools to operate them remotely and exchange valuable data," he continued. "These tools are invisible to the end user but enable the RVMs to work smarter and faster than ever before.”

The needs-based solution that revolutionized reverse vending machines

While some sectors are just beginning to explore the potential of IoT, TOMRA Collection has been on that journey for more than 30 years.

“Our IoT adventure began early because we were rapidly expanding. In the very early days when we only had around 30 machines in a geographically contained area, maintenance wasn’t an issue because we could simply go out to the machines,” says Marius Sommerseth.

“But when TOMRA started to scale up, we needed a more efficient way, so we connected the machines by introducing modems. We never imagined at that point that we would ultimately have approximately 82,000 machines worldwide, or that this first step in connectivity would lead to advances like predictive maintenance and customer apps with real-time information.”

TOMRA’s Internet of Things story

1977, five years after the company’s founding, was the year that TOMRA first equipped its reverse vending machines with computers. It released TOMRA SP, its first self-programmable machine, with a microprocessor inside. This meant if a new drink container was introduced to the market, TOMRA could fax the barcode information to its customers, who could update the machine to recognize it.

Next came the release of T-600 in 1997, TOMRA’s first machine with an embedded modem and ethernet connection. A year later, a digital tool was brought in to automate the IoT process.

By 1999 the company started using ISDN (Integrated Services Digital Network) to carry information. This solved the problem of tying up customers’ telephone lines, minimizing disruption to their businesses.

Reverse vending machines using IoT to talk back

In 2001, support for TCP/IP and Wi-Fi in the RVMs was introduced, and in 2003 TOMRA developed Operation Center, which allowed machines themselves to connect to TOMRA.

“Instead of waiting for us to talk to them, the machines could continuously talk to us and provide status updates. This system was originally developed for some of our recycling centers and we quickly realized how valuable it could be in our RVMs,” says Marius Sommerseth. “In 2007 we incorporated this protocol into all our machines.”

That pivotal moment allowed TOMRA to get valuable data back from its RVMs. TOMRA then needed a way to simplify the management of this data, so in 2008 launched TOMRA Integrated Business System (TIBS) Enterprise Resource Management (ERM) – a graphical interface that produced reports showcasing these insights.

While TIBS ERM was originally designed for internal use, the reports could also prove valuable to customers. This saw TOMRA Collection exploring more ways to use IoT to add value.

Advancing digital capabilities

Two systems were introduced in 2012, TOMRA Plus and TOMRA Trac, providing real-time connectivity and monitoring for RVMs.

As the company was making significant digital advances, it launched a separate digital division in 2014 to accelerate digital development.

“We were making cutting-edge developments at a fantastic pace. We experimented with outsourcing to build even more momentum, but ultimately concluded we had to own these core competencies because it was our area of expertise and we were more successful keeping it in house,” explains Marius Sommerseth.

The IoT platform that opened doors

Although IoT has played a significant role in TOMRA Collection’s solutions for more than three decades, the most significant leaps have come in the last eight years.

The 2017 launch of the IoT platform TOMRA Connect opened new possibilities for the recycling experience. It provided much more value to customers through a range of digital tools:

- Loyalty scheme support: Enabling consumers to redeem rewards.

- Donation function: Allowing consumers to donate their deposit to charity.

- Marketing support: Enabling retailers to show promotions on RVM screens and print discount coupons on refund receipts.

- Status notifications: Showing useful info (full bins, machine stops, printer paper status) and guidance, through an app called Notify+Assist.

- Insights: Pulling business intelligence from big data to show info on queuing time, cleaning quality, recycling volumes and timing.

- Anti-fraud: Combating fraud attempts through real-time validation/devaluation of refund receipts.

This was a huge moment in our Internet of Things journey, not only because we moved to third-generation connectivity and moved our infrastructure to the cloud, but also because it shifted the focus heavily onto customer-centric services.

“Retailers could use the marketing and donation functions to add consumer appeal. Real-time status updates and insights allowed stores to plan ahead and reduce machine downtime, which is important because when machines are full or not working, consumers will go elsewhere to redeem and spend their deposits.”

That same year saw the launch of the myTOMRA app, offering electronic payout of recycling refunds and letting consumers track their returns. In just five years, this fintech app evolved to offer gamification and more payout options, and reached a milestone of 10 million user sessions.

Maximizing digital capabilities to create value

In 2020, TOMRA Collection incorporated its dedicated digital division back into R&D as an integral part of product development. By this point, IoT was enabling a huge network of machines to transfer huge amounts of transaction data, so the next step was to build on that and integrate with customers’ own IT systems.

To facilitate this, a dedicated developer portal was set up, and by 2023 it featured a suite of APIs (application programming interfaces – software intermediaries that allow applications to “talk” to one another):

- Digital Payout: Enabling consumers to redeem deposits through retailers’ own loyalty programs and apps.

- TOMRA Status: Providing real-time status notifications to customers’ devices along with automated guidance.

- TOMRA Consumer Sessions: Storing consumer recycling data in the cloud where it can be accessed almost instantly.

- TOMRA Volume: Gathering drink container count data so customers can ensure they are paid properly for their returns.

Smarter use of data

The amount of data we collect through IoT is phenomenal. We talk a lot about how we use that to enhance the customer and end-user experience, but it’s important also to look at the ways we can use this data in our R&D to develop next-generation RVMs.

“Processing this data can help us look at the anticipated lifetime of machine components. We can compare the impact of cans versus bottles, thick containers versus thinner, bottles with liquid residue, bottles with sugary residue, and more. The data from our IoT connectivity opens a world of possibilities. The natural next step is to use AI and machine learning to help process and interpret that data, and we have already taken big steps forward in this area.”

IoT’s role in future-proofing RVMs

TOMRA gave a snapshot of what’s in store for reverse vending by unveiling several hardware, service and digital concepts at the EuroShop trade fair in February 2023.

These included a new “over-the-air” digital concept, a one-stop-shop for reverse vending intelligence. A prototype app powered by AI provides proactive notifications, cleaning and performance information, and self-configuration features including power saving. This “digital colleague” aims to help achieve zero unplanned downtime.

Another data-driven AI concept called “smart service” was also unveiled, focusing on predictive service and maintenance. By providing service data, it aims to improve efficiency and extend the lifetime of components.

“Right now we are merging our data and creating machine learning algorithms to predict what’s going to happen. This allows for more efficient maintenance planning. Our goal is for our machines to be always available, without the need for a reactive service.”

The talent powering digital advances

TOMRA Collection’s IoT advances have been made possible thanks to its talented multi-disciplinary team of data engineers, data scientists, software developers, front-end developers, and electronics and mechanics experts.

“Our reputation as an innovative global technology provider, and our almost 35 years’ experience working with IoT, has sparked interest from candidates who want to be part of our journey,” says Marius Sommerseth.

“We are a cross-functional team. Our hardware people provide insights, our engineers know every detail of how things are built, our digital team collects the data, our data scientists analyze it, and our developers create the front end so customers can make sense of it.”

What we have achieved to date, and the possibilities that lie ahead, are things we could never have dreamed of when we started connecting machines using the Internet of Things, and our experts have made that possible.

Recap: TOMRA's Internet of Things journey

- 1977: Introduction of TOMRA SP, the first self-programmable RVM

- 1990: Modem add-ons introduced for machines

- 1997: Launch of the T600 with embedded modem, ethernet connection and color display

- 1998: First digital tool introduced to automate process of updates

- 1999: ISDN introduced as communication protocol

- 2001: Support for TCP/IP WIFI

- 2002: OperationCenter tool allowed RVMs to communicate with TOMRA

- 2007: TIBS dialing allows machines to stay always connected

- 2008: TIBS ERM enables graphical interface to produce data reports

- 2012: TOMRA Plus and TOMRA Trac provide real-time connectivity

- 2014: Dedicated TCS Digital division launched

- 2015: Outsourcing explored

- 2017: Launch of TOMRA Connect

- 2020: TOMRA Digital incorporating into The Solution Hub

- 2022: Developer Portal developed for APIs

- 2023: Developer Portal expanded with new APIs / next-generation concepts unveiled at EuroShop

Learn more about TOMRA's reverse vending technology

Sensor technology in reverse vending

50 years of TOMRA's reverse vending innovation