Welcome to Project Boomerang

Join TOMRA Collection on our journey towards product circularity

Earlier this year, we shared how we're approaching the task of reducing the environmental footprint of TOMRA reverse vending machines (RVMs). Now we're ready to provide some insight into our progress along this path.

Enabling circular material flows

When we throw things away, we want them to come right back so that they can be used again, just like a boomerang. In line with this thinking, Project Boomerang is the start of an exciting journey to increase the share of recycled content in TOMRA reverse vending machines (RVMs) and enable more material flows to enter circular loops.

In our quest to source more recycled content for our polymer-based machine parts, we quickly found that such material is hard to come by. However, by establishing partnerships across the plastics value chain, we are now able to send end-of-life polymers for recycling, as well as access recycled material for molding new polymer parts too. That's a win-win for material efficiency!

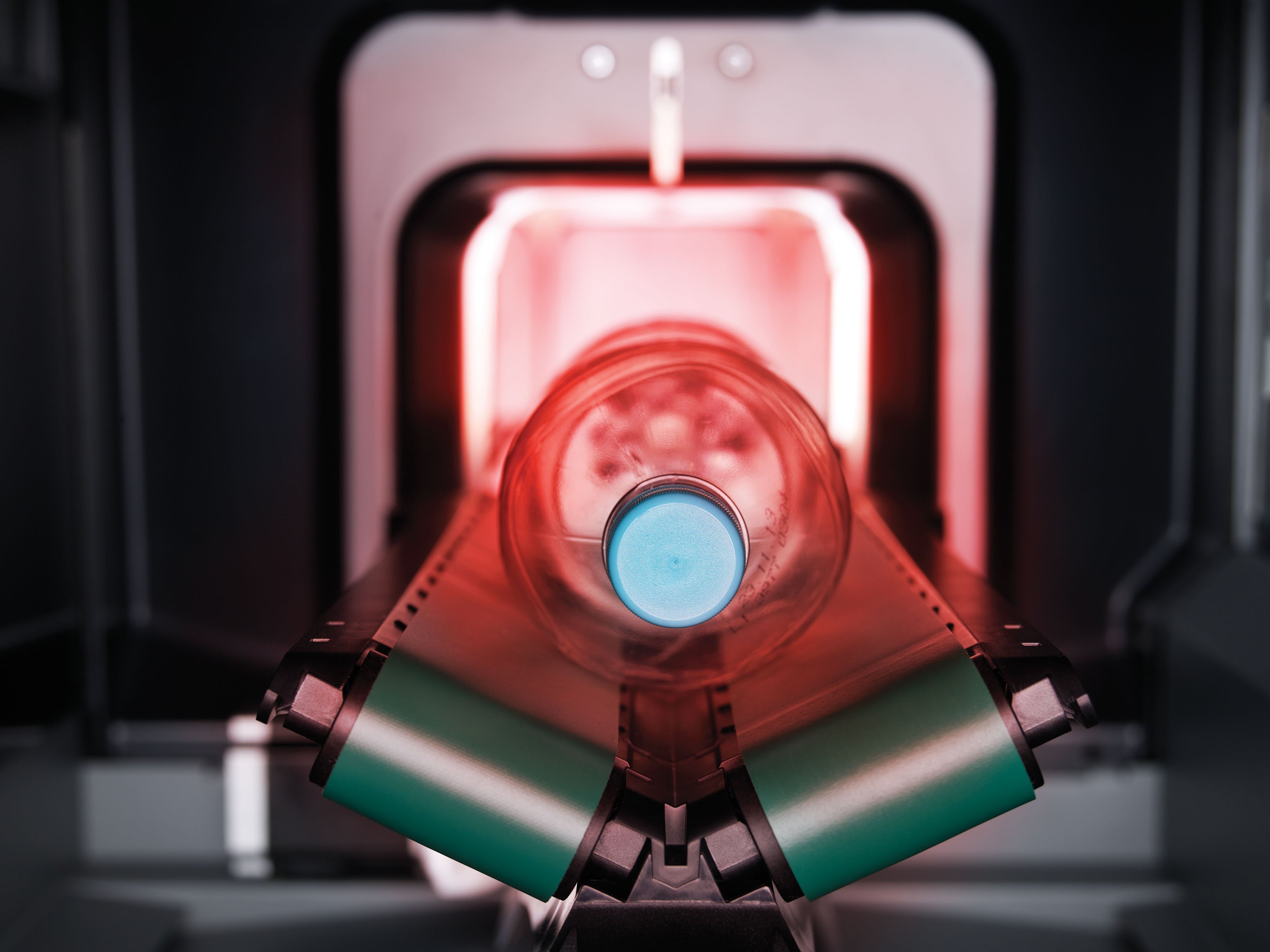

"To get things started," Alexander continues, "we targeted one of the most common components found across almost all TOMRA RVMs: the in-feed conveyor. The idea is to scale things up from there."

The in-feed conveyor is where you place a used beverage container on a single-feed RVM before the container is transported further into the machine.

This component is made up of several pieces of black plastic, which is notoriously difficult to sort, and therefore recycle. Still, the compounds themselves are highly recyclable at their end of life, providing you're able to sort them effectively, among other challenges.

Overcoming these challenges and establishing a recycling loop for this component means we're not only able to begin deploying recycled polymer alternatives out in the field, but, crucially, set in motion a process that is scalable. We look forward to expanding the scope of this work to include many more of the plastic parts found inside our products.

"By exploring the viability and scalability of this circular polymer setup," Alexander adds, "we can gain insight into how to approach the many other material streams associated with our products, not just the plastics. This puts us on a path towards closing the loop on as many material types as possible in pursuit of our ambitious sustainability goals."

We're not only working to redefine product end-of-life processes, we're also creating entirely new value chains.

Collaboration is at the heart of the challenge

Establishing links between the various parts of a material value chain is key for success, as it's the interactions between each of those parts that decide whether a material stream is linear, or circular. Strong partnerships are also likely to shape access to new technologies and materials in the future, so investing in relationships and synergies today is essential to catalyzing the opportunities we might enjoy tomorrow.

Indeed, collaboration and partnerships are something we consider essential to achieving a truly circular economy and, at TOMRA, we're lucky to have knowledgeable partners who are able to challenge us and offer innovative solutions to aid in this journey that we're on.

The exploratory work in Project Boomerang shows us how important it is to collaborate throughout the entire value chain, with significant benefits being derived from discussing the issue of material circularity with key suppliers and service providers. Ultimately, once everyone understands exactly where we're trying to go, we can begin to feed the various perspectives that are on offer into how we design products.

This broader participation is a lever for ensuring higher shares of recycled content are built in from the start and that our products are made from a greater share of materials that are circular at their end of life.

As always, quality and reliability will be an important focus when we design TOMRA products. Alexander Verlo adds that, "Integrating the circularity perspective will inspire a lot of innovation in our product design processes moving forward, too." In this way, sustainability acts a driver for much more than the reduction of environmental impact.

It all starts with design

"TOMRA is a producer of equipment and machines," explains Project Manager, Christina Ek, "and we need to take responsibility for our products, not only during their production, but also during their use, and at their end of life."

As a result, attributes like the end-of-life quality of the materials chosen for use in those machines needs to be considered from the beginning. Additional attention must be given to understanding what kinds of recycling technology exist to be able to sort them down the line, as well as how much energy is required to produce the raw material, and many other considerations. The mantra that has emerged among those working closely with this issue is "It all starts with design."

Our ambition is that this work will unlock new, circular material streams and inspire other manufacturing companies to join us in the Resource Revolution!

For an organization that aspires to Lead the Resource Revolution, this would be no small achievement, and would serve to complement the positive impact that TOMRA products enable.

Looking to the future

Every year, TOMRA reverse vending machines capture more than 45 billion used beverage containers for recycling and reuse across more than 60 global markets. Despite the huge positive impact TOMRA products enable, however, Head of Solution Management, Aleksander Mortensen, says we cannot rest on our laurels.

"Since we were founded back in 1972, TOMRA has been a relentless innovator, using the latest technologies available to solve the tasks associated with reverse vending, always responding to the needs of the time. Today, we are faced with new challenges and new limitations, demanding that we continue this legacy of innovation to reduce the environmental impact of our products without compromising on their quality. But we welcome this task! Innovation is in our DNA."

Despite the huge positive impact TOMRA products enable, it's our responsibility to reduce any negative impacts they might have on the environment.

We hope you'll join us as we continue our journey to reduce the environmental impact of TOMRA reverse vending machines. There are so many more stories that we are excited to share as we make progress on this important issue. This is just the beginning!