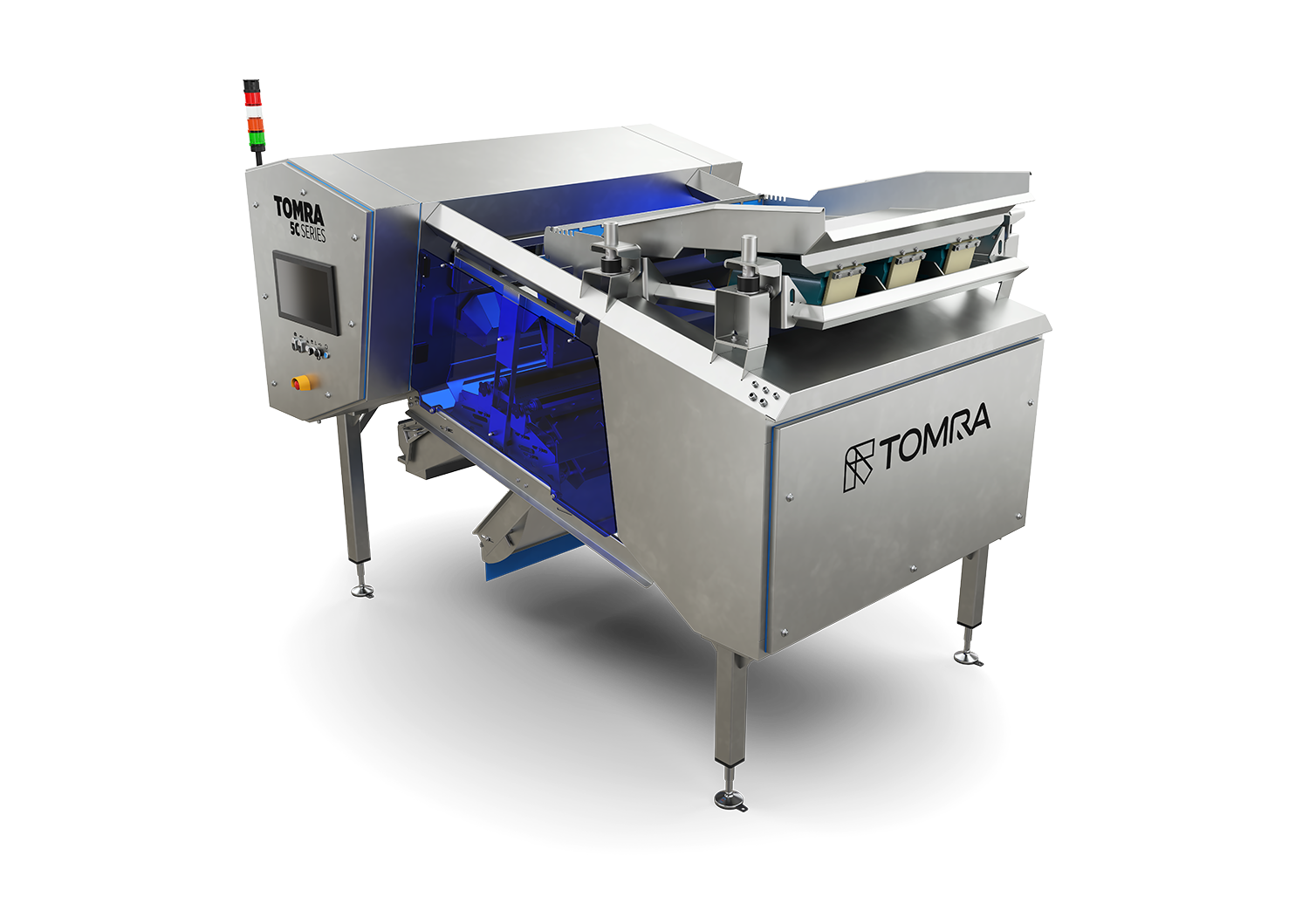

TOMRA 5C

The premier optical sorter for the nut industry, dried fruit and IQF

-

For nuts, dried fruit, IQF, and vegetables

-

High Yield

-

Easy to clean

We maximized operational efficiency, improved food safety, and increased yields with a tailor-made solution for dried fruit, nuts and IQF.

By combining high-resolution lasers with BSI sensors and machine learning, this data-driven machine continuously improves sorting capabilities with every batch it runs.

We have increased this specific product's production - producing at higher volumes, in less time, and with less labor required.

TOMRA 5C Applications

Berries

Dried fruit

Almonds

Cashews

Hazelnuts

Macadamias

Peanuts

Pecans

Pistachios

Raisins

Walnuts

Leafy Greens / Salad

Discover what our customers have to say

Gursoy Findik - Hazelnuts - Türkiye

The Almond Company - Almonds - United States

Click on the touchpoints to learn more about the features of the TOMRA 5C

TOMRA XCD | Platform of the future

The new powerful processing platform using AI and deployed on all new TOMRA Food machines.

Hygienic and open design EHEDG standards

Sanitary design with minimal and curved surfaces that meets EHEDG standards and is more accessible to clean.

Increased capacity and optimized product flow

Ability to do double the capacity of nuts sorted, with a similar footprint.

Improved laser and BSI sensors

New and next generation sensors, identifying not only foreign material but also productspecific defects.

Embedded nitrogen control system for sensor stability

Environmental management system of the optical modules to secure optimal sorting performance.

New design ejection manifold with smart ejection

The TOMRA 5C ejection system enables precise targeting of any type of defect through the smart shape and size ejection parameters.

TOMRA ACT | Easy to use Interface

TOMRA ACT is designed to make sorting adjustments simple and predictable for the user or operator, enabling optimized control.

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are thing of the past.

Speak with us to learn how you can make Every Resource Count!™

.jpg?hash=2c4230f86808855436350f864954082d9ccb93bd7a2ed5430e4a1e945bfd40ca&w=702&h=200&q=75&fit=crop&format=webp)

.jpg?hash=89c48a8efa5f48427a4b0d72972f560cca2216ddb7ca418769f8510040c362ca&w=702&h=200&q=75&fit=crop&format=webp)

.jpg?hash=ebd4b6adb3111daf0997478ef34cd69348c8b3539793f66bb484216623ce11d6&w=702&h=200&q=75&fit=crop&format=webp)